compression test metal|Standard Test Methods of Compression Testing of Metallic : solution ASTM E9 defines testing techniques for compression testing of metals. Using these techniques the parameters of compressive yield strength, compressive ultimate strength, and compressive modulus can all be determined on a variety of geometries of metallic materials. The compressive strength of metallic materials including steel and aluminum can be important in the design of .

webBet with bet365 – Live Online Betting Sportsbook – Latest Bets and Odds. bet365 - The world’s favourite online sports betting company. The most comprehensive In-Play service. Watch Live Sport. Live Streaming available on desktop, mobile and tablet. Bet on Sports. Bet Now on Sports including Soccer, Tennis and Basketball.

{plog:ftitle_list}

WEB4 de nov. de 2019 · E uma casa no Rio, a Low Fire Smokehouse, na Rua da Alfândega, 7, Centro, coladinha a Hamburgueria da Alfândega, trouxe para o Centro do Rio esse prato maravilhoso para os amantes de .

For brittle or nonductile metals that fracture in tension at stresses below the yield strength, compression tests offer the possibility of extending the strain range of the stress .A compression test is one of the most fundamental mechanical tests that can be performed on a material, product, or component. Our compression test machines measure characteristics such as yield strength, ultimate strength, .

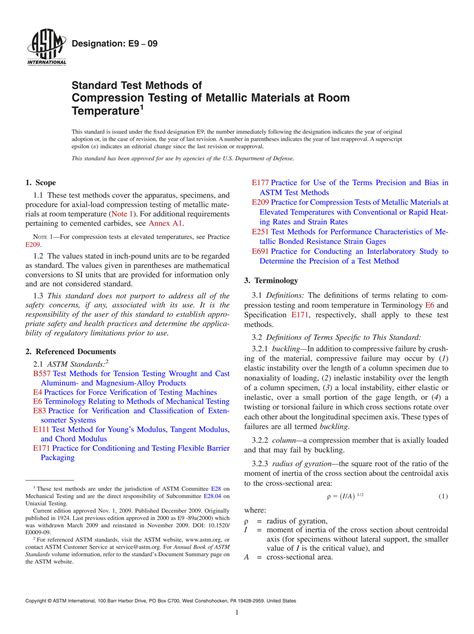

The goal of compression testing is to ascertain how a material responds to a compressive load. This is essential when determining if a material is appropriate for a given task, such as developing structural elements or assuring the quality .Work with us to find the right equipment for compression testing Jump to: Compression Testing Equipment Compression Testing Platens Image Gallery Videos Compression Testing Articles Compression Testing Universal .Compression Testing of Metallic Materials at Room Temperature 1 This standard is issued under the fixed designation E 9; the number immediately following the designation indicates the year of .

ASTM E9 defines testing techniques for compression testing of metals. Using these techniques the parameters of compressive yield strength, compressive ultimate strength, and compressive modulus can all be determined on a variety of geometries of metallic materials. The compressive strength of metallic materials including steel and aluminum can be important in the design of . Metal Compressive Testing. Metal compressive testing involves the following steps: Selecting the test material; Preparing the material; Configuring the test equipment; . A compression test is a type of mechanical testing that measures a material’s behavior under applied forces, usually conducted by applying pressure on a test specimen using . Compression testing is a key part of basic materials characterization. This video discusses the equipment used when performing a compression test and explain. One thing that the wide range of compression test methods have in common is the use of a very short gauge length. Typical gauge lengths for compression samples are 10-13mm, although they can go as low as 5mm. In comparison, the typical gauge length of a tensile specimen is around 160mm. This is due to the requirement to minimise a premature .

Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 .9.13 Compression test. Compression testing is one of the most important tests to determine the behavior of composite materials. Mechanical properties of composite materials can be altered by giving a load to the composite materials, but the properties are difficult to measure directly by a compression test machine. . SUPREMEX–Metal Matrix .

When the material is under compression, the forces on the ends are directed towards each other producing a compressive stress resulting in a compressive strain (Figure \(\PageIndex{2}\)). For compressive strains, if we define \(\delta l=l_{0}-l>0\) then Equation \ref{26.2.3} holds for compressive stresses provided the compressive stress is not . complicated by necking as is the tension test for certain metallic materials, buckling and barreling (see Appendix X1 ) can complicate results and should be minimized. 6. Apparatus 6.1 Testing MachinesÑ Machines used for compression test-ing shall conform to the requirements of Practices E4 and shall be calibrated in compression. The proposed testing fixture was successfully assessed during the compression and cyclic tension–compression of high-strength thin metal sheets as no buckling was observed. Its advantage lies in adapting to change its length with specimen elongation or shrinkage during a test. . Ayllon et al. developed a compression test system with load .

Compression testing is key in materials science for evaluating how materials respond to compressive loads. It helps determine mechanical properties like stiffness, strength, and fatigue life. This overview covers the testing process, material properties, standards, applications, challenges, and best practices.Compression test on a universal testing machine. Compression of solids has many implications in materials science, physics and structural engineering, for compression yields noticeable amounts of stress and tension.. By inducing compression, mechanical properties such as compressive strength or modulus of elasticity, can be measured. [5]Compression machines .

Tensile Stress. Tensile stress is that type of stress in which the two sections of material on either side of a stress plane tend to pull apart or elongate as illustrated in Figure 1(a).. Compressive Stress. Compressive stress is the .Metal additive manufacturing. Chao Cai, Kun Zhou, in Digital Manufacturing, 2022. 7.4.2 Compression. During compressive testing a material experiences opposing uniaxial forces that push inward upon the specimen from opposite sides. The loading forces in compressive testing are the opposite of those in typical tensile tests, but both experimental measurements are .Compression Testing of Metallic Materials at Room Temperature 1 This standard is issued under the fixed designation E 9; the number immediately following the designation indicates the year of .

Tension and Compression Testing

Homogeneous compression: No friction is present at the contact surface; Compressive instability: Failure due to work softening of the metal; A widely accepted test to determine the compressive strength under maximum applied stress is the Mohs hardness test. By understanding both tensile and compressive stresses, as well as their respective .A compression test is a method for determining the behavior of materials under a compressive load. Compression tests are conducted by loading the test specimen between two plates, and then applying a force to the specimen by moving the crossheads together. . It is considered the measure of rigidity or stiffness of a metal.

compression test concrete

The test sample is generally placed in between two hard metal bearing blocks that distribute the applied load across the entire surface area of two opposite faces of the test sample and then the plates are pushed together by a universal testing machine causing the sample to flatten. . In compression test the properties such as elastic limit . This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp.

View common materials compression testing standards and solutions for performing compression tests on composites, metals and plastics by using specialized fixtures on universal testing machines. . test system enables lab-based studies of high-speed rail operating environments Read the Article. Applications. Materials Applications Test Type . Unfortunately, large-strain, in-plane compression is difficult to attain in sheet materials because of buckling modes that develop. Compression testing of sheet material generally takes one of two forms. The first approach emulates the geometry of the bulk compression test, which has a length-to-diameter ratio of 3 (ASTM E9-89a, 2000). For sheet metal characterization, the compression test at normal direction of the sheet can be done by means of the layer compression test. One of the advantages of this test is that the equi-biaxial stress point for accurate yield locus definition can be computed, assuming that the hydrostatic stress has no effect on the plastic deformation [1].Hardmetals — Compression test. Buy. Follow. Table of contents. Foreword. 1 Scope. 2 Normative references. 3 Terms and definitions. 4 Principle. 5 Symbols and designations. 6 Apparatus. 7 Test piece. 8 Procedure. 8.1 Rate of stress increase. 8.2 Determination of proof stress. 8.3 Determination of ultimate compressive strength.

The ring compression test is a conventional test for identifying the friction law for metal forming applications. This test is very widely used but has a significant disadvantage. In particular, if the friction stress is high, then a sticking region occurs over a.

Standard Test Methods of Compression Testing of Metallic

Compression Test

Ache e baixe recursos grátis para Carinha Triste. 99.000+ vetores, fotos de arquivo e arquivos PSD. Grátis para uso comercial Imagens de alta qualidade Você pode .

compression test metal|Standard Test Methods of Compression Testing of Metallic